Lighting Industry

In the lighting industry, gas-filled glass bodies are widely used. Although conventional incandes-cent lamps are increasingly replaced by alternative lamps, gas-filled lamps, such as gas discharge lamps and energy-saving lamps, will stay in use for the long term.

Gas discharge lamps will continue to be used in many professional applications due to their high luminous flux combined with high efficiency, excellent color index and small design.

The correct gas filling of the gas piston is essential. Incomplete filling or the presence of harmful residual or purge gases affects the quality of the product with respect to its photometric values and time of service.

Analysis of the ignition and burning behavior as well as evaluations of the color of the plasma (for detection of defined gas types) can be economically integrated into the production process by applying a GNT solution.

Conventional methods require the destruction of the test object and can therefore only be used for spot control.

GNT systems enable rapid and 100% testing by using the plasma technology without destroying the product. This stabilizes product quality, increases the effectiveness of production and cuts costs.

The GNT developer team can adapt the test systems to the individual requirements. The specificity of the product, the geometric dimension, the type of gas used and the deviations to be identified are thus taken into account in high-voltage generation and plasma evaluation. Hence, GNT systems can be adapted to almost all applications.

The evaluation of the plasma allows fast and reliable tests for each individual product. Intermediate testing of semi-finished parts also saves costs by early eliminating defect products from the further manufacturing process.

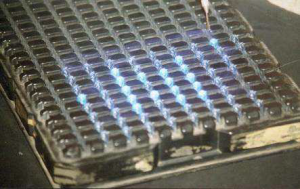

The picture shows the application of the plasma test in a lamp production. After sealing the glass bulb, the tightness of each product is tested.

Final inspection and initial ignition of fluorescent light tubes:

Final inspection and initial ignition of fluorescent light tubes can be performed in a single action. The ignition of the gas takes place rapidly and without blacking effects on the glow electrodes. In this process, ions are formed and remain in the tube for a long time, thus facilitating the first ignition in the customer’s application.

This initial ignition can be integrated into the production process or carried out as part of the initial control.

Rapid test of low-voltage halogen lamps:

GNT plasma generators PG100Basic, PG100BasicM and PG1200 together with HV-Probe HVP-2 are suitable for easy and rapid visual inspections of light tubes. The HVProbe is approached to the illuminants and beyond the function test, the corresponding color of the light is visually assessed. Deviations of the gas filling are identified immediately by non-existing or altered plasma light.

Particularly in the case of smaller halogen lamps or discharge lamps, large numbers of pieces can be checked in a cost- and time efficient manner.

Du muss angemeldet sein, um einen Kommentar zu veröffentlichen.