PG 1203IP – for Pharmaceutical Industry – Highvolume Vacuum Tests – Plasmagenerator and Detector

Non-destructive Vacuum Testing in the Pharmaceutical Industry

The PG1203IP Vacuum tester was specifically developed for non-destructive vacuum testing in the pharmaceutical industry.

This is the first vacuum-testing system that goes beyond Pass/Fail evaluation to additionally offer quantitative analysis.

Reliability, high throughput and easy system integration characterize the PG1203IP. Special emphasis was placed on user-friendly operation.

Electrical and mechanical system integration and customizing is supported by GNT and/or our partners, who can offer standard and customized mechanical equipment for the production line.

Both the plasma generation and the evaluation are carried out using the latest signal processing algorithms and high-performance processors. In addition, there are extensive possibilities for data documentation and connection to existing automated systems.

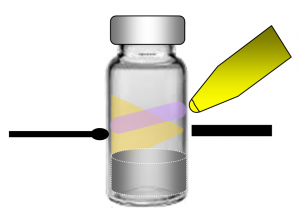

The figure illustrates the mechanical arrangement to test a vial. The electrode of the generator (tip) is applied to the surface of the vial. A ground electrode will guide the way for the plasma. The optical fiber receives the plasma light and sends it to the optical detector.

Features:

- Automatic system for gentle and non-destructive measurement of gas-content and vacuum with PASS technology

- High testing speeds (up to 10 samples per second)

- Manual & semi-automatic modes for spot/single measurements and testing

- Extensive safety and self-test functions

- Most independently of the ambient light conditions with PASS detection

- Non-hazardous operation due to special modulation

- Programmable database for product formats and comprehensive data storage

- Easy operation via display, keypad and incremental encoder

- Output of results via display and interfaces

- IP50; sealed construction allows easy cleaning and disinfection

- A range of plasma electrodes (probes, tips) available

- Most independently of the ambient light conditions and interference-free signal transmission with fiber optics (SMA connector)

- Stepper motor control for automated electrode level setting

- Interfaces to PLC connection via M8 connector, optically isolated

- Host computer, network and other interfaces available

- Service indicator and real-time clock

- User-specific firmware customizing available (frequency, output, pulse-controlled operation)

- High Voltage Generation max. 50kV, 380kHz, Modulation 5600 Hz

- Vacuum testing (air): 1 – 400mBar

- Internal memory: 800MBytes

- Dimensions and weight 200(W) * 120(H) * 250(D) mm3, 2,7 kg

- Part number: 4050426000210

Application

- Automated in-line measurement of vacuum in glass container

- Spot / single testing to identify leakage / breakage of glass container

- For quality control and mass testing in pharmaceutical industry