PG 1202G – Automatic System for Vacuum and Gas Content Tests

Plasmabased Testsystem

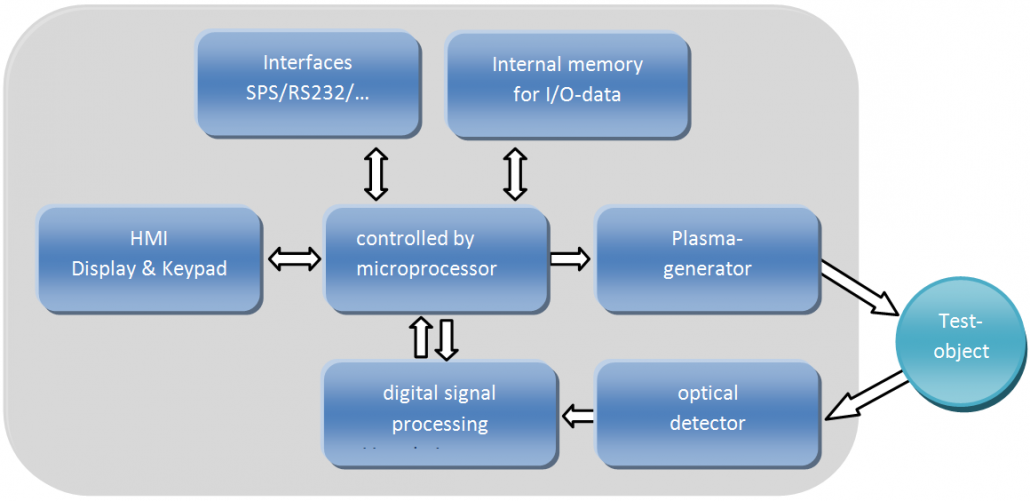

The PG 1202G gas testing unit combines a processor-controlled plasma generator, a highly sensitive optical plasma detector with digital signal processing, and an easy-to-operate system for controlling all of the unit’s functions.

PG 1202G detects the plasma even if the intensity is far below the ambient brightness. The test results are displayed and are optionally available at an interface for further processing. The PG1202G automatically determines the minimum plasma energy level and thus allows the determination of the internal pressure level within less than 100 milliseconds.

Depending on the application, the device can be operated manually, semi-automatically or automatically by remote control via an interface and can thus be used in the laboratory as well as in production or for quality control. The measurement parameters can be adapted within wide limits to the respective task via the comfortable menu in order to ensure optimum performance with minimum stress on the tested products.

The convenient menu allows setting limits for good / bad classification and provides counters as well as an output of the measured values via an interface.

Naturally, all settings are protected by a PIN code to prevent unauthorized manipulation. Advanced signal-processing algorithms and high-performance processors control the plasma generation and analysis. This specialized method of plasma detection allows the system to operate under normal lighting conditions without the need for shades or dim-out.

Features:

- Automatic system for gentle and non-destructive testing of gas-content and vacuum with PASS technology

- High testing speeds (up to 15 samples per second)

- Manual & semi-automatic modes for spot/single measurements and testing

- Extensive safety and self-test functions

- Most independently of the ambient light conditions with PASS detection

- Non-hazardous operation due to special modulation

- Convenient to handle – suitable bow- and prop-up-handles

- Easy operation via display, keypad and incremental encoder

- IP50; sealed construction allows easy cleaning and disinfection

- A range of plasma electrodes (probes, tips) available

- Interference-free signal transmission with fiber optics (SMA connector)

- Interfaces to PLC connection via M8 connector, optical isolator – host computer, network and other interfaces available

- Service indicator and real-time clock

- firmware customizing available (frequency, pulse-controlled operation)

- High Voltage Generation max. 50kV, 380kHz, Modulation 5600 Hz

- Vacuum testing (air) 0,1 – 400mBar

- Dimensions and weight 200(W) * 120(H) * 250(D) mm3, 2,7 kg

- Part number: 4050426000197

Application:

- Automated in-line testing of vacuum or gas content in glass container

- Spot / single testing to identify leakage / breakage of glass container

- For quality control and mass testing

Operating Voltage : 110 – 240 V/AC 50 – 60Hz

Dimension : 200(W) * 120(H) * 250(D) mm